Eastman - Paint Protection Film (PPF) Installer Software

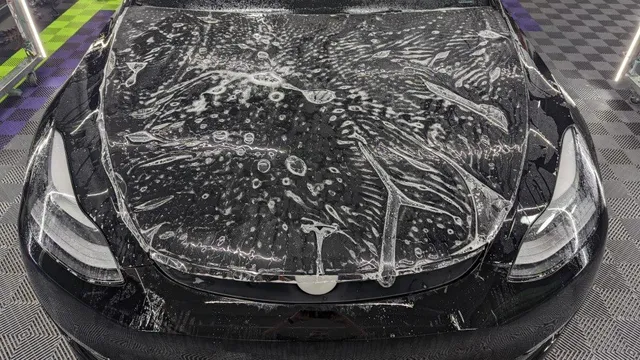

Eastman manufactures several products called Paint Protection Film (PPF)—a thin film applied to the surface of a vehicle like a second skin.

The people who install this film range from single-person shops—where competition with other installers is fierce—to large vehicle dealerships that apply PPF to every vehicle before it hits the lot.

PPF comes in large rolls that are fed into a cutting plotter. The software feeds patterns to the plotter and is often tied to proprietary vendor libraries in exchange for film purchases.

Eastman's film technology, expertise, and customer service were already ahead of the competition, but their existing software was difficult to use, and their pattern library wasn’t as mature.

In 2019, Eastman asked us to help in two specific areas:

- Build a world-class application that reflected the quality of Eastman's film.

- Decrease the time it takes to create, verify, and distribute new film patterns.

This project became a perfect example of the "right way" to tackle a complex problem. We loosely followed the classic design thinking phases:

- Empathize

- Define

- Ideate

- Prototype

- Test

At the start, we weren't sure what the final deliverable would be—but we were given the freedom to explore and figure out what the next steps should be.

Step 1: Multi-disciplinary team listens to client stakeholders

We spent the first two weeks conducting panel interviews with stakeholders across Eastman—including finance, product, sales, and marketing. Our team included designers, developers, data scientists, and account managers who would stay on the project throughout.

These sessions gave us a broad, holistic view of the problem space and helped us build continuity for the next phase. But one group’s perspective was missing: the actual users.

Step 2: Conduct field research with actual users

I led this phase by crafting a research plan focused on in-person fieldwork.

Our research team traveled to high-volume, highly experienced installers in Texas, where we observed them using both Eastman’s software and a key competitor's.

What we learned was eye-opening:

- Installers were being charged per cut—even for unusable cuts.

- A Bentley dealership was blacklisted after ordering fewer rolls than their cut volume implied.

- Competitors used localized sales data to open their own shops, undercutting existing customers.

- Installers were afraid to talk about using Eastman products online due to fear of retaliation.

We also saw how seemingly simple workflows were overly complex, confusing, or just broken.

We brought these findings back to Eastman to talk not only about fixing issues—but about how to position their software as an indispensable tool for their customers.

Step 3: Ideate and create low-fidelity prototypes

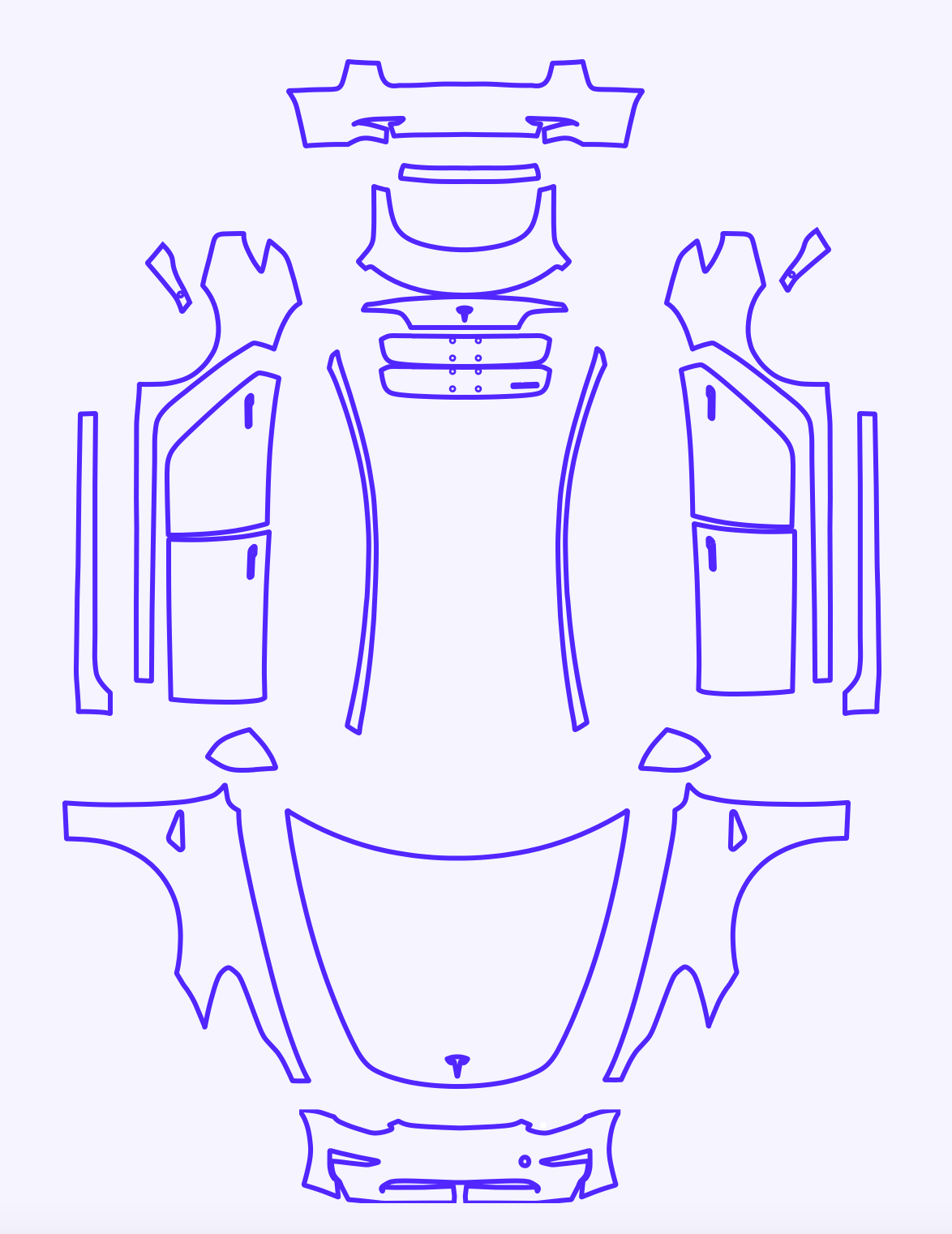

After multiple iterations, I landed on a novel layout for vehicle patterns: an exploded “skeleton” view that visually mirrors a vehicle's real-world layout.

As often happens in consulting, I was temporarily moved to another project. During that time, another designer took over the visual design work. When I returned, it was to lead the next research phase.

Step 4: Test the prototype with actual users

I wrote a new research plan for this phase and conducted two rounds of usability testing.

Since our participants were remote (and we didn’t want to travel back to Texas), I selected Lookback as our testing platform. It allowed for remote moderated testing and included powerful features like timestamped observer notes, screen and video recording.

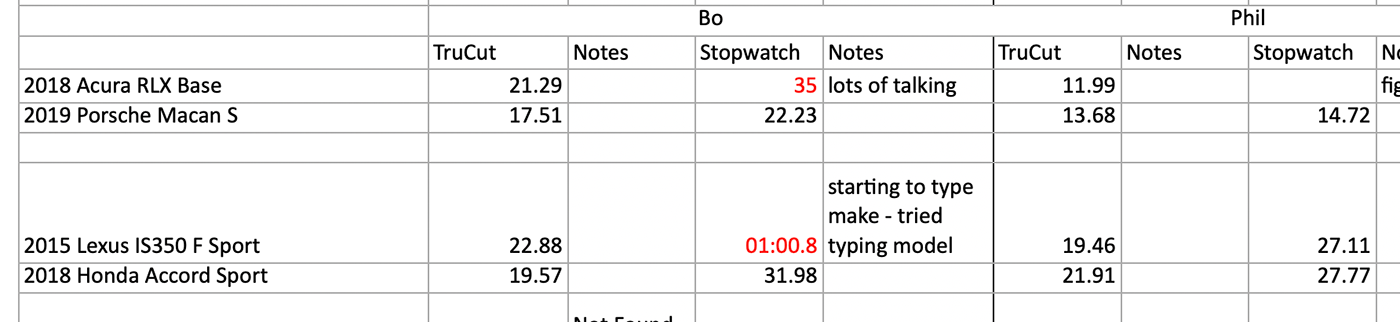

Our first round tested a new pattern for selecting year, make, model, and trim using a coded prototype. We timed interactions and compared them against the existing app to ensure any new interaction pattern was as good—or better—than what we were replacing.

The results were clear: the new pattern was slightly slower but resulted in fewer errors. That was an acceptable tradeoff for the team, so we moved forward.

The second and final test I ran was a full end-to-end evaluation with users familiar with Eastman's current application.

Results and Recommendations (PDF)

The results?

Eastman launched a newly rebranded application—“Core”—at the 2019 Las Vegas Auto Show! This beta version was already in the hands of users and has since continued to evolve through regular releases, guided by the roadmap we helped define through deep user research.

You can sign up for a trial if you want to check out Core for yourself.

Conclusion

This project was complex and high-stakes—but with a solid research foundation, we reduced risk, aligned teams, and delivered a product that continues to grow today.

Get in touch